Stamping Vs Milling . The higher material utilization of stamping helps keep costs down. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Where possible, designing high production volume parts as stampings minimizes production costs. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. Learn about surface finishes, die types, and. In metal stamping processes, the types differ from one another, depending on what shape they achieve. This is done in order to create complex designs for. This usually comes down to quantities and part design. Machining is going to be more. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. This press then uses pressure and die to transform the metal into the predetermined shape. Which is right for my parts?

from www.iqsdirectory.com

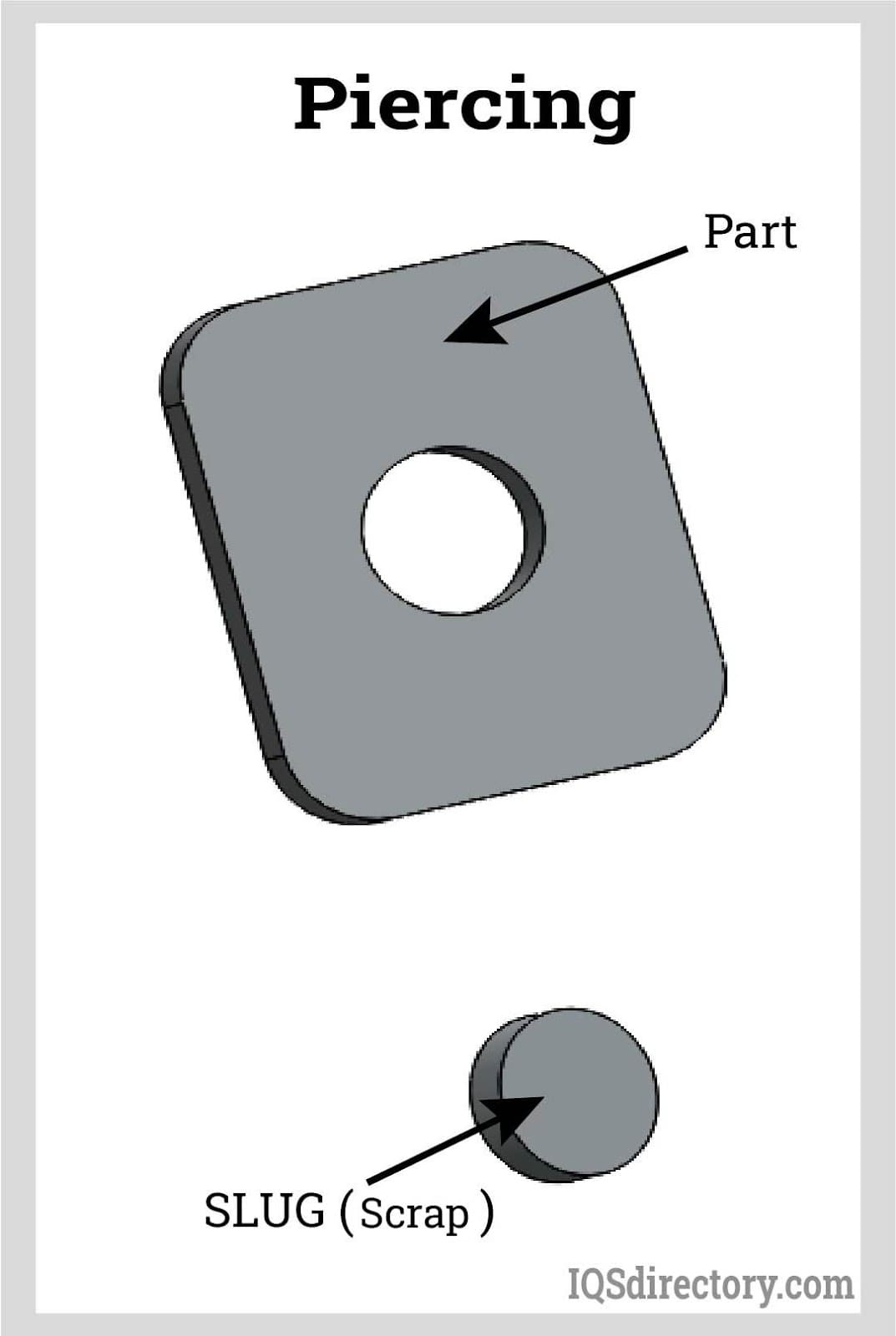

With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. In metal stamping processes, the types differ from one another, depending on what shape they achieve. Learn about surface finishes, die types, and. The higher material utilization of stamping helps keep costs down. This press then uses pressure and die to transform the metal into the predetermined shape. Machining is going to be more. This is done in order to create complex designs for. Where possible, designing high production volume parts as stampings minimizes production costs. This usually comes down to quantities and part design.

Die Stamping What is it? Process, Steps, Progressive vs. Transfer

Stamping Vs Milling The higher material utilization of stamping helps keep costs down. Machining is going to be more. This is done in order to create complex designs for. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. The higher material utilization of stamping helps keep costs down. This press then uses pressure and die to transform the metal into the predetermined shape. Where possible, designing high production volume parts as stampings minimizes production costs. Which is right for my parts? This usually comes down to quantities and part design. Learn about surface finishes, die types, and. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. In metal stamping processes, the types differ from one another, depending on what shape they achieve.

From stock.adobe.com

Sheet Metal Stamping Tool Die for Automotive Precision Parts on The Stamping Vs Milling This press then uses pressure and die to transform the metal into the predetermined shape. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Machining is going to be more. The higher material utilization of stamping helps keep costs down. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers. Stamping Vs Milling.

From www.youtube.com

Differences Between Horizontal and Vertical Milling Machine. YouTube Stamping Vs Milling By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. Learn about surface finishes, die types, and. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. With. Stamping Vs Milling.

From www.jktoolinc.com

Stamping Tooling — JK TOOL Stamping Vs Milling Learn about surface finishes, die types, and. In metal stamping processes, the types differ from one another, depending on what shape they achieve. Where possible, designing high production volume parts as stampings minimizes production costs. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. The higher material utilization of stamping helps keep costs down. This. Stamping Vs Milling.

From dynamicdiesupply.com

Progressive Die Stamping Vs. Transfer Die Stamping Dynamic Die Supply Stamping Vs Milling This press then uses pressure and die to transform the metal into the predetermined shape. This usually comes down to quantities and part design. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Machining is going to be more. This is done in order to create complex designs for. Where possible, designing high. Stamping Vs Milling.

From dunkirkmetalproducts.com

Metal Stamping vs. Metal Fabrication Dunkirk Metal Products Stamping Vs Milling This press then uses pressure and die to transform the metal into the predetermined shape. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. This usually comes down to quantities and part design. Where possible, designing high production volume parts as stampings minimizes production costs. Machining is going to be more. The higher material. Stamping Vs Milling.

From blog.thepipingmart.com

Stamping vs Blanking of Metal What's the Difference Stamping Vs Milling In metal stamping processes, the types differ from one another, depending on what shape they achieve. Which is right for my parts? The higher material utilization of stamping helps keep costs down. This is done in order to create complex designs for. Learn about surface finishes, die types, and. With stamping, the lighter the gauge and the smaller the part,. Stamping Vs Milling.

From www.strappack.org

Comparing Turning and Milling Techniques Strappack Stamping Vs Milling Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. This press then uses pressure and die to transform the metal into the predetermined shape. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. Which is right for my parts? With stamping,. Stamping Vs Milling.

From www.plantautomation-technology.com

Deep Draw Stamping Process Machine Tools Cutting And Forming Stamping Vs Milling This press then uses pressure and die to transform the metal into the predetermined shape. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Where possible, designing high production volume parts as stampings minimizes production costs. Learn about surface. Stamping Vs Milling.

From readingplastic.com

CNC Milling Precision Plastic Machining, Die Stamping, Custom Stamping Vs Milling This usually comes down to quantities and part design. The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. Where possible, designing high production volume parts as stampings minimizes production costs. Learn about surface finishes, die types, and. With stamping, the lighter the gauge and the smaller. Stamping Vs Milling.

From www.thefabricator.com

Die Science Friction and heat in metal stamping Stamping Vs Milling Learn about surface finishes, die types, and. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. This usually comes down to quantities and part design. This press then uses pressure and die to transform the metal into the predetermined. Stamping Vs Milling.

From www.precisionstampinginc.com

Stamping vs. Machining What's the Difference? Precision Stamping Inc Stamping Vs Milling With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. This usually comes down to quantities and part design. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. In metal stamping processes, the types differ from one another, depending on what shape they achieve. Where possible, designing high production. Stamping Vs Milling.

From www.lathematters.com

Milling vs. Grinding How Are They Different? Stamping Vs Milling With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. Machining is going to be more. Learn about surface finishes, die types, and. Where possible, designing high production volume parts as stampings minimizes production costs. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. The metal stamping process. Stamping Vs Milling.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Stamping Vs Milling Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. In metal stamping processes, the types differ from one another, depending on what shape they achieve. Where possible, designing high production volume parts as stampings minimizes production costs. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. This press then. Stamping Vs Milling.

From www.iqsdirectory.com

Die Stamping What is it? Process, Steps, Progressive vs. Transfer Stamping Vs Milling Learn about surface finishes, die types, and. Machining is going to be more. Where possible, designing high production volume parts as stampings minimizes production costs. This press then uses pressure and die to transform the metal into the predetermined shape. In metal stamping processes, the types differ from one another, depending on what shape they achieve. By understanding the key. Stamping Vs Milling.

From www.researchgate.net

Comparison of a laser trimming, b cold press trimming, and c hot Stamping Vs Milling Which is right for my parts? Where possible, designing high production volume parts as stampings minimizes production costs. The higher material utilization of stamping helps keep costs down. This is done in order to create complex designs for. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. Some examples of stamping techniques used include. Stamping Vs Milling.

From www.esict.com

Progressive vs. Compound vs. Transfer Die Stamping Engineering Stamping Vs Milling Machining is going to be more. In metal stamping processes, the types differ from one another, depending on what shape they achieve. By understanding the key differences between stamping and machining, designers, manufacturers, and engineers can determine. This press then uses pressure and die to transform the metal into the predetermined shape. Where possible, designing high production volume parts as. Stamping Vs Milling.

From www.glomacht.com

what are the different types of milling machines? GLOMACHT BV Used Stamping Vs Milling Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. This press then uses pressure and die to transform the metal into the predetermined shape. With stamping, the lighter the gauge and the smaller the part, the tighter the tolerances become. The metal stamping process also referred to as metal pressing, consists of taking flat sheet. Stamping Vs Milling.

From www.thomasnet.com

What is Metal Stamping? A Guide to Processes, Steps and Types of Presses Stamping Vs Milling The metal stamping process also referred to as metal pressing, consists of taking flat sheet metal and feeding it into a stamping press. This press then uses pressure and die to transform the metal into the predetermined shape. Some examples of stamping techniques used include punching, coining, embossing, bending, blanking, and flanging. With stamping, the lighter the gauge and the. Stamping Vs Milling.